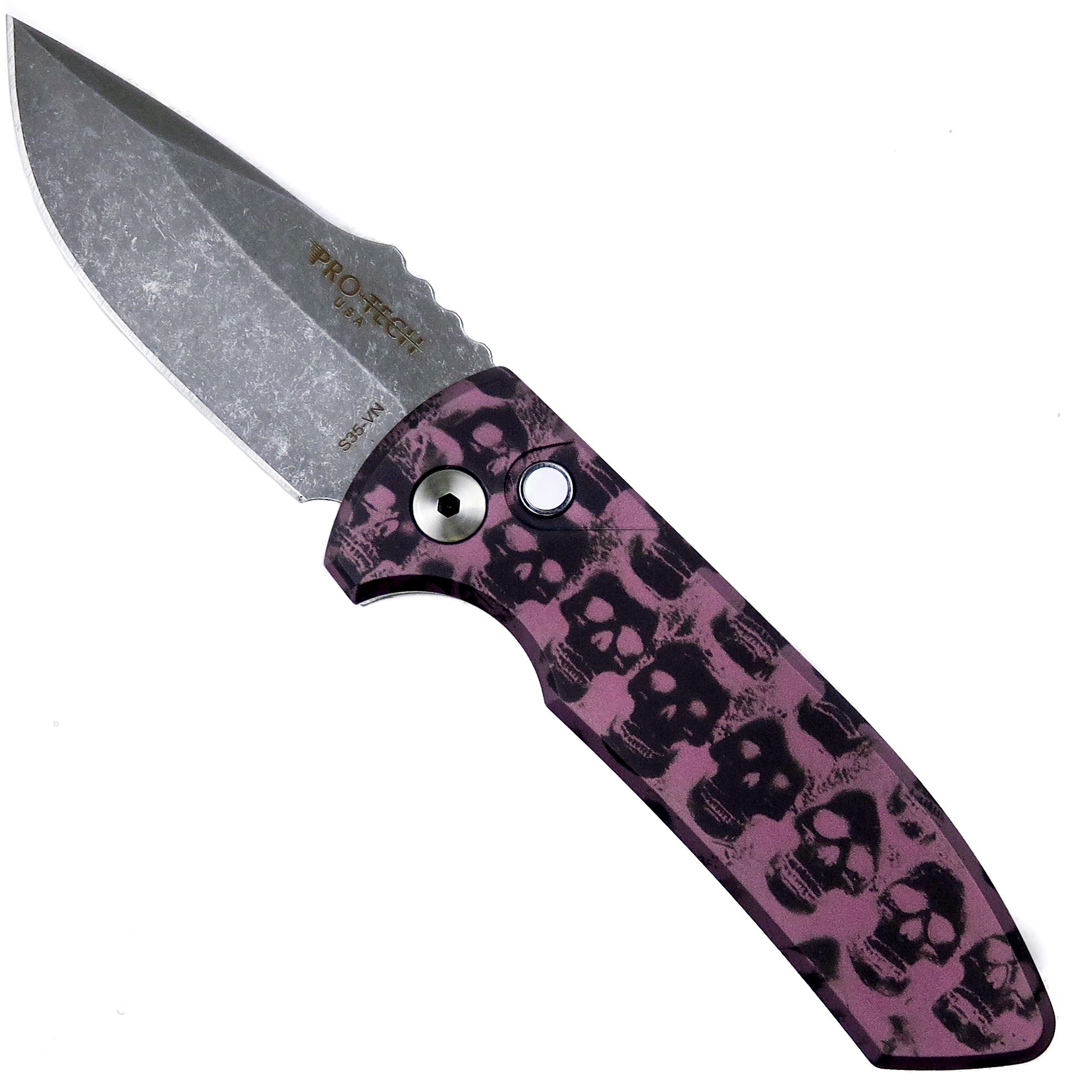

Knife Review: Pro-Tech Skulls #5 SBR Automatic Knife

Posted by SD on Apr 14th 2020

The Pro-Tech Skulls #5 SBR Automatic Knife

Pro-Tech Knives, LLC is a family owned knife company that has been building high quality American Made knives since 1999. Each of their knives is a blend of the finest materials available, mixed with their commitment to craftsmanship. Their knives are always built with the most current high-tech manufacturing process that includes CNC Machining, Wire EDM, and Laser Cutting. The high-tech components are assembled and hand fit by dedicated and caring craftsmen right in their factory. Yes, that does mean that they are all made in the United States of America!

One of the unique aspects about Pro-Tech is that they manufacture small batches of knives so that they can take the time to individually hand fit and finish each knife to a level that you are rarely going to find in a factory knife. Their production knife models offer the best design, function, and value of any knife that you are going to find on the market today. They even have custom art knives that are individual pieces of art. Each of their custom, limited-edition knives are a showpiece of heirloom quality. But, no matter which of their knives that you choose to purchase, they, and we, are confident that you will be very satisfied with your purchase.

Their collection of knives is always changing. They are always working on new designs form collaboration partners, new variations of classic designs, new inlay materials, Damascus blade choices, and many more.

Today we will be discussing one of their newest releases, the Pro-Tech Skulls #5 SBR automatic knife. This knife is in stock at BladeOps, but it will be going quick, and quantities are limited. If you are hoping to get your hands on one of these, you’re going to want to hurry.

The Blade:

The blade on this Pro-Tech is made out of the high-quality CPM-S35VN stainless steel. This steel is produced and manufactured by the high-quality manufacturer Crucible Industries. They are known for their high-end steels that are designed specifically with high-end cutlery in mind. This is one of those steels which means that you are not going to be able to go wrong—you’ll get all of the characteristics that you could desire out of the blade.

The first thing about CPM-S35VN steel is that it wasn’t Crucible’s first attempt at nailing an ideal steel. The father of this steel is CPM-S30V steel. However, while the original steel had plenty of good qualities to it, Crucible didn’t like the drawback—it was hard to sharpen. So, they started over and we got this nearly perfect steel.

The biggest difference between the two steels is that S35VN steel has a much finer grain structure. Plus, Crucible threw in small amounts of Niobium, which is where the N in the name comes from. Both of these aspects of the steel mean that this is going to be a breeze to sharpen. Always an advantage.

The next thing amount CPM-S35VN steel is that it does have a nearly perfect balance between edge retention, hardness, and toughness. This balance is hard to achieve, but Crucible did it, with seemingly ease.

Lastly, this steel has very high levels of corrosion and stain resistance. These characteristics are going to lead to this knife being much more low-maintenance than many others.

The CPM process is a process that Crucible came up with that essentially enhances all of the other great aspects of the steel. With this process, it will be slightly easier to sharpen, tougher, and even more durable. Really, it’s just the cherry on top of a fantastic steel.

The blade on the Pro-Tech Skulls #5 SBR has been finished with an acid wash. This is nearly the same thing as a stonewash finish, except before it has been stonewashed, the blade undergoes an acid treatment. This acid treatment works to darken the blade, which means that the texture and appearance of the stonewashing is going to be much darker. Sometimes, this is even referred to as a Blackwash, because of how dark it is.

Not only does the acid treatment elevate the appearance of the blade, it also adds an oxidized barrier, which means that it is going to increase the corrosion resistance of this blade. You also get the typical low-maintenance characteristics of a stonewash, with the textured appearance hiding the scratches and smudge that occur over time. The acid wash does make this overall knife appear tougher than it would be with a regular stonewash or other finish.

The blade on the Skulls #5 SBR has been carved into the popular blade shape: the drop point. Just like the name implies, the point on this blade shape is dropped. The dropped, or lowered aspect, is going to provide the control that fine detail work requires. Plus, you will have more control over all of your cuts and slices, which is something that you cannot go wrong with. While the spine on most drop points angles downward slightly from the handle to the point, this one is slightly different. The spine starts out going straight out from the handle in a row of thick jimping. This row of jimping is going to help provide even more control. After the row of jimping, the spine angles down to the point.

The next defining characteristic of a drop point blade shape is that it has a very broad tip. This is where the strength of the blade shape comes from. Drop points are known for begin strong, for being able to take on the toughest of tasks, for never having to back down. Of course, this broad tip is also one of the biggest drawbacks to the blade shape. Because of the thickness, you aren’t going to be able to easily pierce with the SBR. Of course, with all of the other great characteristics, this shouldn’t be too big of an issue.

The last great thing about a classic drop point blade shape is that the belly is massive. This extra size leads to a better ability to slice with.

The Handle:

The handle on this version of the SBR is made out of 6061-T6 aluminum. Aluminum is a very popular handle material, because it does offer a lot of characteristics that are easily desired form a knife. For starters, aluminum is very corrosion resistant, which means that maintenance is going to be much easier. It is also a durable and strong material. It doesn’t and won’t feel cheap or flimsy in your hand while you are trying to use it. This can sometimes happen with more modern materials such as GFN.

Then we get to the 6061-T6 aluminum alloy. This is the strongest alloy of aluminum and it offers the highest yield resistance. This means that all of those great qualities that we just talked about are going to be further enhanced. This is going to be strong, tough, and incredibly corrosion resistant.

Unfortunately, there are still some disadvantages to having an aluminum handle. For starters, it is prone to getting scratched and dinged. The other disadvantage is that it does have a high level of conductive properties. This means that when it is cold, the metal is going to feel extra cold. In some environments, this coldness is nearly unbearable.

The handle does feature a Peter Keller anodized handle in a unique skull-them motif. For starters, the anodization process offers a lot of great qualities as well. This is a chemical change to the surface of the aluminum, which means that the color is not going to peel off like other coatings. Plus, it almost creates a barrier in the same way that a coating would. This means that the handle is going to be stronger, tougher, and even more corrosion resistant than the original aluminum. Plus, while plain aluminum is prone to getting scratched, this anodization process is going to limit the amount of scratches that it does accumulate.

However, with this version of the SBR, the qualities of the anodization process are not the stars, instead, it is the appearance of the anodization. The anodization has created a scheme of purple and black. Across the face of the handle are images of different black skulls on a purple background.

The handle is basic, which is needed for such a unique appearance. There is no lanyard hole, there is a large finger guard, and a typical finger groove. The spine is flat and slowly curves toward the butt.

The Pocket Clip:

The pocket clip that is statically designed for tip up carry only on the traditional side of the handle. This does mean that the SBR is not going to be ambidextrous friendly, because the clip is single position. The clip is also not a deep carry, which can be a disadvantage.

The pocket clip is black, which goes well with the black and purple schema of the handle. It is slightly tapered toward the end of it. Near the top of the clip, it is skeletonized so that you can see the screws through the clip. The screws that keep it in pale are silver, which doe match the rest of the hardware on this SBR.

The Mechanism:

This is an automatic knife, which does mean that it is not going to be legal in all states, cities, or areas of the United States. Automatic knives fall under a strict set of laws in the United States. Because of this, it is your responsibility as the purchaser and then as the user to know your local knife laws before purchasing or carrying this knife.

This is a push button automatic, which means that all you have to do to deploy the blade is push a small button that sits on the front of the handle. On this version, the push button has been inlayed with a white mother of pearl.

There are plenty of advantages to having an automatic knife, but the biggest one is that you will be able to bring it into play quickly and easily.

The Specs:

The blade on this knife measures in at 2.625 inches long with a handle that measures in at 3.875 inches long. This means that the overall length of it while opened is going to measure in at 6.5 inches long. This is on the smaller side of knives, especially ones that are as tough as this particular one. Of course, this Pro-Tech is made out of quality materials, which means that even though it is on the smaller side of the spectrum, you shouldn’t have any issues relying on this one. Because of its smaller length, it does weigh in at a mere 2.9 ounces. The best weight for an EDC sits between 3 and 5 ounces. As you can see, this is going to be a little bit lighter than that sweet spot. However, like I mentioned, the high-quality materials are tough enough that you will still be able to easily rely on this SBR. Plus, you won’t be weighed down in the slightest.

Like any Pro-Tech, this special edition one is made in the United States of America. This means that you will be able to easily rely on it without questioning the quality. It also shows a little bit of patriotism, which is always a good idea.

Conclusion:

This special-edition automatic knife features a Peter Keller anodized aluminum handle in a unique skull-theme motif, a drop point style blade in an acid washed finish and the pocket clip is designed for tip up carry.

The Pro-Tech SBR (Short Bladed Rockeye) is a Les George designed push-button auto that boasts a stout 1/8" thick blade stock. Each model sports stylized pockets milled into the spine and the deep finger groove promotes excellent grip security. Lastly this specific model also includes a mother of pearl inlay on the firing button.

This brand-new Pro-Tech is in stock at BladeOps right now. You can purchase all Pro-Tech Auto knives here.