Knife Review: Chris Reeve Knives Pacific Fixed Blade Knife

Posted by SD on May 5th 2020

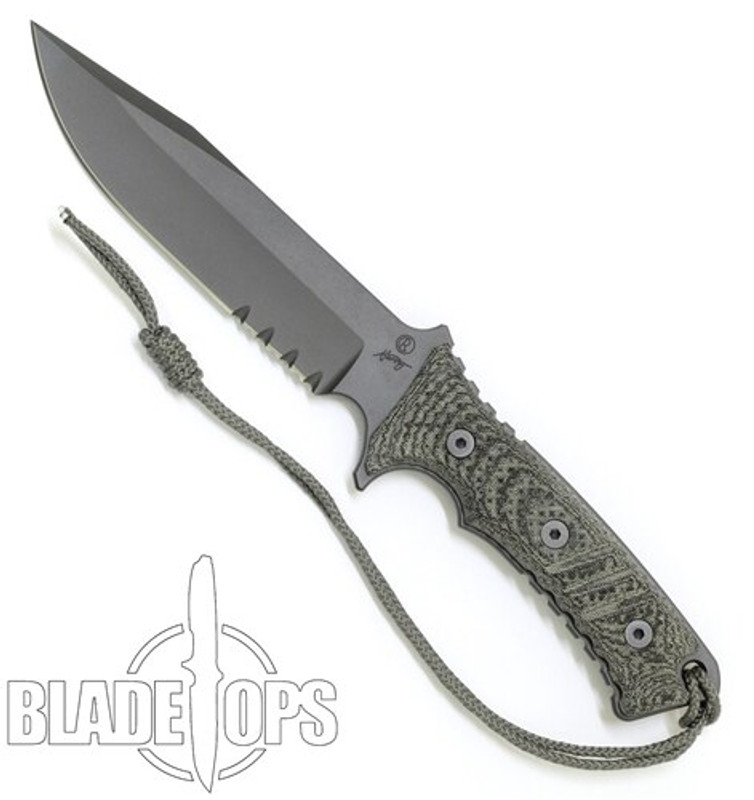

The Chris Reeve Knives Pacific Fixed Blade Knife

Chris Reeve knives says, “Chris Reeve Knives is a production knife manufacturer. As a production company, we design and produce our own knives, as opposed to a custom knife maker who may work with a client to design and bring his or her knife idea to life. Our knives are produced in a combination of hand and machine work out of our machine shop in Boise, Idaho.”

Chris Reeve Knives began operations on January 1, 1984, in a one-car garage in Durban, South Africa, when Chris moved from full-time Tool and Die Maker/part time knife maker to full-time knife maker. For a couple years he was the only employee but gradually and steadily, the company has grown to reach its present position as a well-equipped manufacturing company and a noted brand in the industry.

The road between 1984 and today has not always been smooth. For many years, the endeavor was under-funded but with determination, Chris and Anne put all they had into producing the best knives possible, within the resources available. In March 1989, they moved from their native South Africa and settled in Boise, Idaho. That move in itself was a major undertaking but vital for the future of the company.

The company says, “Chris has always "pushed the envelope". Whether on a motorcycle or behind a belt grinder, he dreamed of being a world champion. He did not win a motorcycle world championship but in many respects, the standing of CRK today represents one. His induction into the Cutlery Hall of Fame in June 2015 could be considered his championship trophy. The single thought in Chris' mind has always been to design every model with deliberation, taking into account how the knife works, its intended purpose and the most appropriate materials. On this foundation, CRK is a vibrant business, has a great staff of well-trained employees, and remains a company with a worldwide reputation for raising the standards bar - "pushing the envelope" - for the industry.”

Today we will be talking about the Chris Reeve Knives Pacific Fixed Blade knife.

The Blade:

The blade on this knife is made out of CPM S35VN stainless steel. This steel was designed by Crucible, in collaboration with Chris Reeve, which makes it no surprise that it is used on this Chris Reeve knife. The two got together to make a steel that was similar to S30V steel, but with some major improvements. S30V steel was known for having very high corrosion resistance levels. It was also known for having the perfect balance between hardness, toughness, and edge retention, which is a harder combination to achieve than it seems. This is because the harder the steel is, the less tough that it is going to be. S30V steel had created one of the best balances between these two characteristics.

However, because the steel was so hard, it proved complicated to machine or to sharpen. This is what Chris and Crucible decided to fix. They started with a similar formula, but this time, they used a finer steel structure. They also added a little bit of niobium into the steel matrix, which brings out the hardness but makes it easy to sharpen still. This steel is going to still have the best characteristics that the original version of the still did, but it is definitely improved. When it comes to such a high-end knife, such as this one, you are only going to want the best steel.

This steel is going to get the job done. With the Pacific, you will know that it has the best steel around.

The blade has been finished with a dark grey KC Gun Kote finish. This is a protective coating of choice that is often used in gun protection instead of blade protection. This finish was originally made for military and aerospace use, but the products have since become the standard in metal coatings and finishes. This finish’s is both impact and solvent resistant, which does mean the blade is going to be incredibly durable.

This finish is matte, which does reduce glares and reflections. It is going to prolong the life of the blade because it will form such a protective barrier between the environment and the steel. This will also make it easier to maintain, because all you will need to do is wipe down the blade. You won’t really have to worry about oiling the blade. And since it is such a strong coating, it shouldn’t’ be prone to scratching off.

The blade has been carved into a clip point blade shape with a hollow grind.

The clip point blade shape is the second most popular blade shape on the market, and for good reason. It is very similar to the drop point blade shape, especially in terms of versatility. Of course, the clip point blade shape excels at piercing, which is really what sets this knife apart.

The spine of the blade runs straight form the handle to about ¾ of the way up the blade. At this point, it angles sharply down toward the tip, which does create a lowered tip. This portion that is angled is referred to as the clip, because it looks as if it has been clipped out of the blade itself. Not only is this the namesake of the blade shape, but the lowered tip also allows you to have more control over the blade, allowing you to do some fine detail work. Of course, since this is such a large knife, you probably won’t be doing too much super small detail work with it. The lowered point also means that the tip is going to be finer and sharper than a drop point. This fine and sharp characteristic is going to be the feature that allows it to excel at piercing. It creates less drag, which allows you to pierce more quickly.

The last major advantage of the clip point is that the belly is large enough to allow you to excel at slicing. With all of the clip point’s features, you will be able to trust this blade when it comes to combat.

The hollow grind is popular, especially when it comes to hunting or combat knives. The sides of this grind actually curve inward until they meet, which helps give a razor-sharp edge That being said, the grind is not the most durable grind and can dull more quickly than others.

The blade does have a slight combo edge. There is a small portion near the handle that has serrations. The serrations are a little bit thicker and will help you excel at sawing through thicker materials that you come across in combat, such as ropes, seat belts, or even branches. The rest of the blade is a plain edge, which will allow you to slice.

The Handle:

The handle on the Pacific is made out of canvas micarta. This material is created when thin layers of canvas are soaked in a phenolic resin and then set. This process creates a material that is strong, lightweight (which is crucial for a knife that you are going to be carrying with you into the field), and even looks classy. It is able to look classier than most other knife handle materials because it is the canvas that shows through, instead of a plastic-y looking material. This material is also durable and tough, which is exactly what you will need out of a fixed blade.

While micarta does have plenty of great aspects, it does have a few drawbacks. The absolute biggest one is that when the process is first finished, it doesn’t have any surface texture. This means that a lot of time and hand labor is going to need to go into carving in texture on this handle, which is going to make it a more expensive product. One of the other bigger drawbacks that micarta has is that it does tend to be brittle. This means that if subjected to too hard or sharp of an impact, it may begin to break down and crack.

The color of the Micarta is a sandblasted black. This means that it has a few different colors worked throughout the Micarta. There is black mottled throughout, but there is also a lighter Olive Drab or tan color.

The handle is designed to give you a super solid grip. The first section on the spine has a row of thick jimping. The rest of the spine has a slight curve to it that extend to the butt of the handle, which is squared off. The belly is more drastic and definitely sports enough grip-enhancing characteristics that will ensure that no matter how tough the task is, you’ll have a grip. There is a large finger guard, which is necessary with a blade that is going to be razor sharp. Right after the finger guard, there is a deep finger groove.

The rest of the handle curves inward toward the butt. Again, near the end of the belly, there is a row of thick jimping. The face of the handle has three indents going across about 2/3rds of the way own the handle. This is going to give you more texture, which will also lead to more grip. There is a large lanyard hole in the butt of the handle, which will fit almost any lanyard that you could want it to.

The Mechanism:

This is a fixed blade, which does mean that there is no mechanism to help open or close the knife. There are a few benefits to having a fixed blade. The first is that the blade can be larger, longer, and thicker. This creates a stronger blade, which is, in turn, going to be able to take on a wider variety of things.

A fixed blade is also easier to maintain. This is mostly due to the fact that there is no mechanism inside of it. This means that you don’t have to worry about the hinge when you are cleaning, because there is no hinge. There are also no inside parts that can rust or break down. Really all you will ever have to do is wipe down the handle and blade. With the blade’s coating, you shouldn’t even have to oil the blade. That’s how easy it is.

Lastly, a fixed blade can take on a wider number of tasks. This is because it is tougher, larger, and more durable.

The Sheath:

The sheath that comes with this Chris Reeve knife is an ACU Combat Master sheath which is made by SpecOps Brand. This sheath is known for being a utility sheath that will give you everything you need for the field. The sheath is known to adapt to nearly any M.O.L.L.E. type systems. When it comes to a combat knife such as this one, the ACU Combat Master sheath is the perfect companion.

The Specs:

The blade on the Pacific measures in at 6 inches long, with a blade thickness of .22 inches. The handle thickness measures in at .150 inches thick. The overall weight of this knife is 11.6 ounces, which is definitely on the heftier side. Of course, with a knife like this, you need it to work instead of being worried about the weight that it may carry.

Conclusion:

The Chris Reeve Pacific continues the proud tradition of honoring the elite military. This Reeve/Harsey collaboration is the civilian version of a knife created to celebrate the 50th Anniversary of 1st Special Forces Group (Airborne). The knife boasts a 6" clip point blade with a handle of textured, black canvas Micarta. The double row of serrations on both sides of the blade allows it to cut aggressively through fibrous material. The back of the handle has a glass breaker. Comes with an ACU Combat Master sheath produced by SpecOps Brand.

This Chris Reeve Knives Pacific fixed blade is currently in stock at BladeOps, but quantities are going quickly. Click here to buy yours now.